The wind force It is called (along with solar energy), one of the biggest champions of the energy transition. In fact, wind is currently one of the major players in many electrical systems in the world. Without going any further, in Spain Wind power was the main source of electric power in 2021with about 23.3% of the total production according to data from Red Eléctrica de España.

But the truth is that if we want to continue to decarbonize the economy, that share must increase significantly. This is established by the objectives of the National Integrated Energy and Climate Plan (PNIEC), which states that Wind installed capacity in Spain doubles for the year 2030, Going from about 28 GW current to 50. Of course, the prospects for global installation also indicate significant growth.

However, as we continue to create new gardens, the oldest gardens are beginning to reach the end of their useful life. According to WindEurope data as of 2020, About 34,000 wind turbines installed on European soil are 15 years old or more. Bearing in mind that the useful life of wind turbines is usually between 20-30 years, this takes us to the near future where many of these machines will be dismantled. To put us in perspective, in 2021 396 megawatts of wind energy has been decommissioned in EuropeBut expectations speak of the dismantling of 11,400 megawatts during the next five years. It will grow significantly in size.

As a result, in the next few years, we’ll be hanging out with hundreds of these old machines. But don’t panic: right now 80-90% of wind turbines are recyclable. We are talking about materials such as steel, copper, aluminium, cast iron, concrete and plastics that are not technically challenging and can be recycled using existing processes and facilities. However, the backbone is in the blades, which is a more complex component for recycling due to its manufacture in composites (glass fibres, carbon fibres, resins and other polymers), which require more complex and expensive processes.

Giving a second life to wind turbine blades

Follow one of the basics of caring for the environment known as Rule of three rupeesThe first step we should take to avoid collecting too many used scoops together is to reduce the amount we use. However, given the decarbonization needs of the economy, future installation projections and the prospects for decarbonization described above, barring a catastrophe, this seems unlikely.

The next step will be reuse. What can we do with used wind turbine blades? This is the question that many startups and universities around the world are starting to ask. In fact, the possibilities are very diverse.

Due to its shape, size and the fact that it is made of durable and relatively light materials, its use as an architectural element or as furniture is undoubtedly the most widespread. Some of these examples have already been installed, while others are just ideas from architectural studios or universities.

Children’s gardens

In Rotterdam, the Netherlands, we’ve got this curious children’s playground made from reusable wind turbine blades that the city council has promoted. As you can see, many of the shovels were cut into pieces to serve as tunnels, towers, bridges and slides for the kids to enjoy. It is a pioneer place, as it was built in 2009. It is the park that you can also see in the cover photo.

Wikado Stadium in Rotterdam. Source: Superuse Studios.

Later, other similar parks were built at other nearby sites.

Playground in Terneuzen. Source: Superuse Studios

Street Furniture

Also in Rotterdam, this time on Willemsplein, comes another example of wind turbine blades being used as street furniture. In this case, nine full wind turbine blades were used to create public benches. As it turns out, it is not cut (only painted red), although it is also true that it is compatible with models of small wind turbines.

Public benches made of wind turbine blades, Rotterdam.

Some examples of less ambitious furniture but with amazing designs are those that come to us from the company ANMET.

A seat made of wind turbine blades. Source: ANMET

bridges

Use Bridge shovels It’s perhaps one of the most intriguing and exciting apps out there, but it’s also one that involves the most work. Here, the cipher becomes a structural element of the bridge and the need for more complex calculations arises.

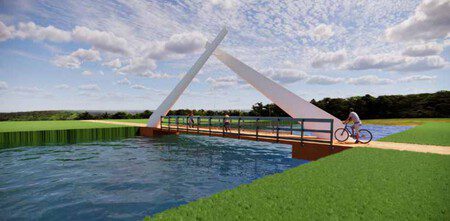

A bridge built with wind turbine blades. Source: REwind

According to its creators, it is not only a way to find a second life for blades, but it can become cost-competitive with respect to other traditionally built bridges. Designs can be very diverse.

pedestrian bridge design. Source: REwind

Cable-supported bridge design. Source: REwind

Curtains or ceiling tiles

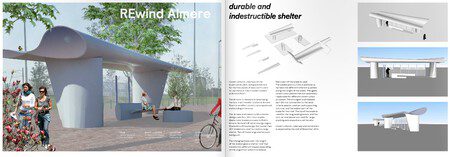

One of the applications with great potential is the use of blades as an umbrella for different applications. Due to its shape, it is relatively easy to make cuts on the bucket which allows it to be used as a board. The following example corresponds to a bicycle rack made of part of a shovel. It is located in the port of Aalborg in Denmark. REwind also has a design in your catalogwhich can be used as a bus stop.

The bike rack is made of wind turbine blade. Source: Siemens Gamesa

A canopy made of wind turbine blades. Source: REwind

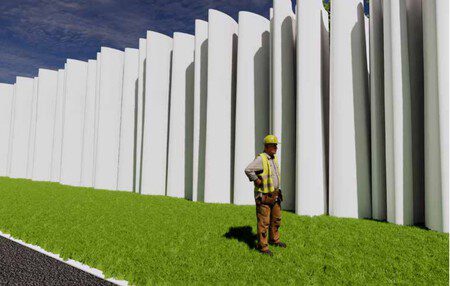

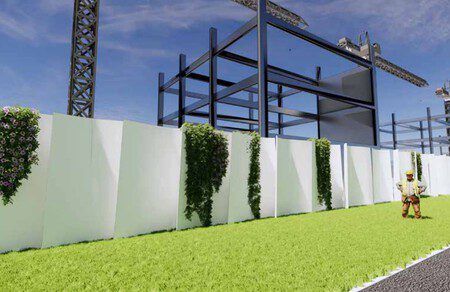

acoustic barriers

Another interesting application that REwind has in its catalog is the use of blades as sound barriers. Sliced blades can be used to create typical acoustic walls typically used to separate roads from pedestrian areas.

Acoustic barriers built with discarded blades. Source: REwind

Even since the shovels are hollow, you can even fill them with soil and include vegetation.

Towers for power lines

An intriguing concept, which also somehow preserves the usage associated with power generation, is the use of wind turbine blades as electric towers to transmit electricity. Even network members at the Georgia Institute of Technology in Atlanta built a 20-foot-tall prototype.

Now, after checking that the blade can withstand the weight and loads of the cables, the engineers plan to build a new prototype using the 36-meter blade.

Introducing the use of blades as electric towers. Source: Re-Blade

Size can be a limitation

As can be seen from the images, many of these projects rely on micro-scale blades, which are compatible with blades used on older models and are reaching the end of their useful life.

However, as the years go by, the blades will be pulled out grow up and grow up, which opens up a range of possibilities for its reuse: Why not make a car canopy instead of a bike canopy? Or much longer bridges?

However, reusing larger blades also has other handicaps such as logistics. In the end, the transportation cost can rise to collect the loose blades (due to the need for special transportation), as well as to process them in the workshop and transport them to the final site.

This problem in turn can make the use of other technologies more attractive such as grinding or crushing, which in turn greatly limits the possibilities of reuse. The other alternative usually is to cut the lawn bucket, and get different pieces of a size that meet the usual (and cheaper) transportation standards.

When it is not possible to reuse

But, for one reason or another, reuse is not always possible. This could be due to structural damage to the blade that does not allow for reuse, because the logistical cost can go up dramatically (it must be remembered that many wind farms are located in remote locations) or directly because there is no significant market for blade-based solutions for reuse.

Be that as it may, the industry is already aware of this problem and has begun to develop projects that allow the application of a third of Three rupees: Recycling. In this sense, at the level of Spain, projects have already been submitted to build blade recycling plant in Lyon and another in Navarra.

Moreover, looking to the future, manufacturers are already developing so-called 100% recyclable blades, designed from scratch to allow for a simpler and cheaper recycling process. This is the case of Siemens Gamesa and its project Recyclable blade Or from the specialized LM Wind Power blade manufacturer ZEBRA . project.

“Beeraholic. Friend of animals everywhere. Evil web scholar. Zombie maven.”