success story

Drafting between sister companies01/06/2022

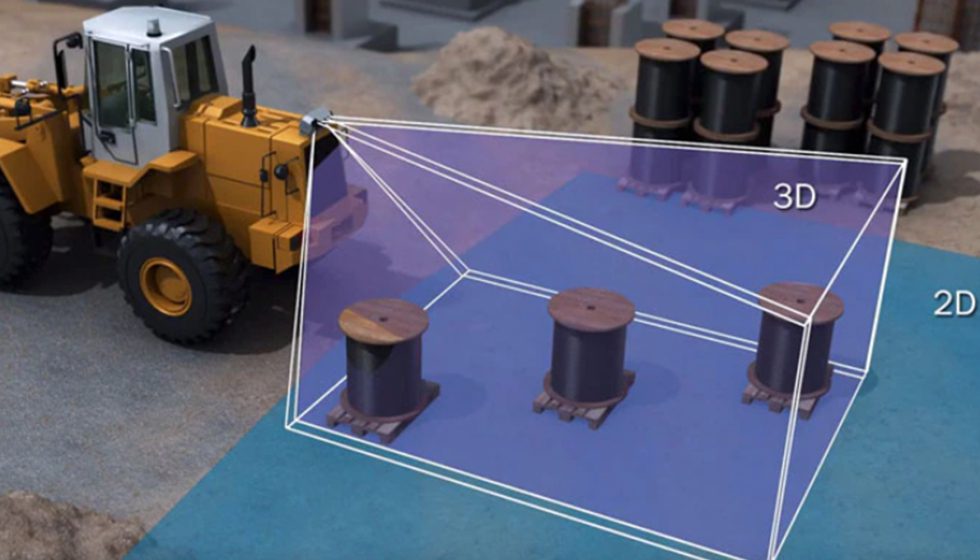

Forge handlers are conveying and handling machines that can weigh up to 1,000 tons. Their payloads, which can reach 350 tons, are still incandescent and can reach temperatures of 1,200 degrees Celsius. Therefore, operational safety when transporting this type of part is essential. 3D rendering of illness It provides road and transport handlers drivers with a better view of their safety, especially in the back of the machine.

company Dango and DenenthalHeadquartered in Siegerland (Germany), manufactures large machinery for its clients in the metallurgical and steel industry. These massive transfer handlers transfer blocks of hot steel to a forging hydraulic press the size of a chapel. Due to the dimensions of the machine, it can be difficult to keep an overview of the ergonomics. The large size of the piece means that the molding and transfer operations done with the processor must be done precisely at all times, and to achieve this, it relies on Sick’s 3D vision technology.

Driver information

When it comes to reversing aids, Dango & Dienenthal has an active camera system: Sick’s Visionary-B 3D vision sensor. Based on the holographic principle, this system is based on a technology that reliably detects structures, objects and obstacles within 3D space. The system displays each camera image as a live broadcast on the screen, and smart algorithms ensure that a warning signal is given only when important objects are detected.

Some of these obstacles may be logistical materials, vehicles or people in the driving area behind large handling machines. Countries, containers or manned forklifts in the driving area are among the most common causes of collision. The Sick Visionary-B driver assistance system operator can configure which objects trigger the alarm and which do not.

Sick’s solution captures the scene with short exposure times, thus avoiding delays. The 3D camera prevents sudden or sudden events from appearing on the image undetected. Another advantage of this 3D technology is the absence of moving components. Conventional stereos do not need rotating mirrors or a moving object in front of the 3D camera to give reliable collision warning. The principle behind Visionary-B is actually similar to that of human vision, says Mohammed Albayrak, one of Sick’s application engineers, in which the human brain fuses two horizontally placed objects to build a three-dimensional image.

Blind Spot Early Warning System

In general, it must be ensured that the 3D driver assistance system is not adversely affected by the harsh environmental conditions of the molding process. However, reliability must ensure that it does not distract the driver with an audible or visual warning of any event or offense occurring in the rear image. That’s why these systems should focus on alerting the driver only in the most dangerous situations.

Speed is also a major factor in the journey from the reheating furnace to the forging press. The longer the transportation time, the faster the steel block will cool. This also applies to unexpected stops or error handling. In the worst case, the component must be returned to the oven to bring it back to the target temperature (about 1200°C). Taken together, supply chain delays for these challenging components have a direct impact on production times and lead to a measurable decrease in energy efficiency.

“Beer enthusiast. Subtly charming alcohol junkie. Wannabe internet buff. Typical pop culture lover.”